We are delighted to announce that the Southwest Minority Supplier Development Council (MSDC) has approved our application for certification as a Minority Business Enterprise (MBE). Minority businesses are 51% ethnic minority owned and operated by an individual(s) meeting U.S. citizenship … Read More

LTD Material Breaks Ground on New Facility

On March 8th, 2023, we broke ground on our new manufacturing facility in Austin, Texas that will span over 45,000 square feet. Our partners in the industry, the architects and engineers of the new facility, former local government workers, as … Read More

LTD Material, LTD Material is Expanding

From the Austin Business Journal Semiconductor sector supplier LTD Material to ramp up production, hiring with new building Dozens of new hires expected By Mike Christen – Staff Writer, Austin Business Journal Jul 21, 2022 The expansion comes as Central Texas’ semiconductor sector … Read More

COVID-19: Essential Business Classification

LTD Material, LLC meets the definition of an “Essential Business” under the guidance issued by the Mayor or Austin in order #20200324-007 as well as the U.S. Department of Homeland Security Cybersecurity & Infrastructure Security Agency (CISA) as well as the Department of Defense.

COVID-19 Update

LTD Material is closely monitoring the development and changing of the coronavirus (COVID-19) situation. To safeguard the health and well being of our LTD Material team members and our visitors we have implemented strict country restrictions for international business travel. In addition, we want to inform you of the restrictions of non-business critical visitors to LTD Material sites.

Ceramics

We have vast experience with SiC, Ytria, Sapphire, Alumina, Zirconia, Zirconia Alumina, etc. We work with all major suppliers.

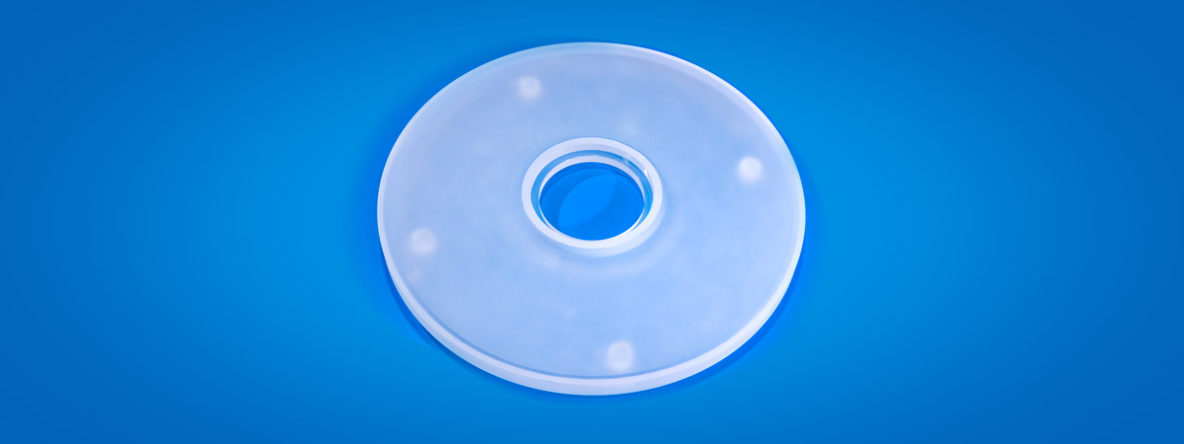

Fused Quartz

LTD Material uses mainly quartz from Heraeus and GE but also have relationships with other material supplier such as Pacific Quartz, Feilihua and others. Below we provide some information on material purity for some of our suppliers’ material.

Quartz Surface Enhancement

Our proprietary process has given our customers increased MTBM in CVD applications. This surface treatment provides better film adhesion allowing the tools to run longer. Some customers have reported the tool can run 50% longer before delamination occurs and particle defects spike.

Quality Control

At LTD we recognize that quality products are the output of conscientious producers. Therefore, we strive to move quality reporting to the process step producing the required features to meet our customer needs. This means that we train our production personnel to evaluate the quality of the part before and after they perform their process step. When a non-conformity is found at any stage of the process, a team of stakeholders is assembled to document next steps, root cause and corrective action(s). This activity fuels our continuous improvement process.