Engineering Support

LTD Material’s engineering and technical sales team average over 25 years of industry experience. Our expert engineers can create custom-designed solutions based on your unique application. We also offer options to improve and/or extend the product life of existing parts.

Overview

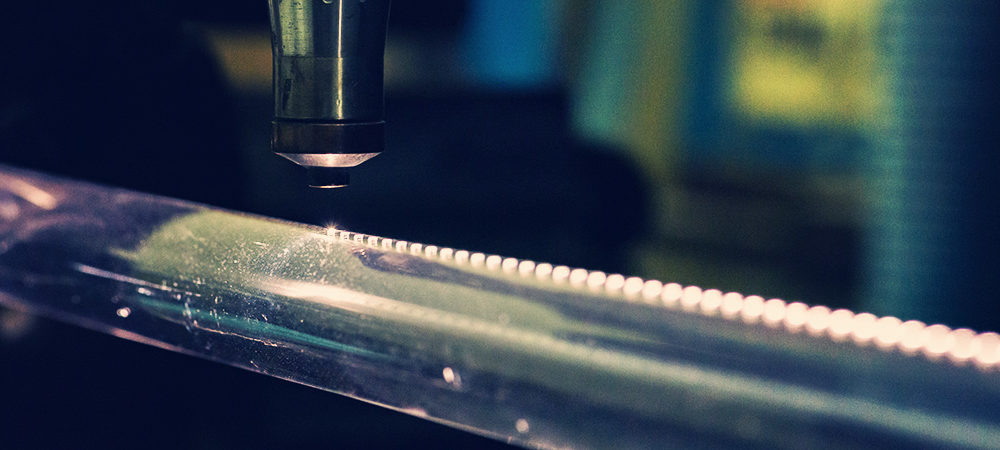

Our Production Facilities Can Support You Through the Entire Life Cycle of Your Design. We can work with you to understand your application needs. We can then apply our diverse fab experience to define optimal materials and propose novel approaches to improve tool performance.

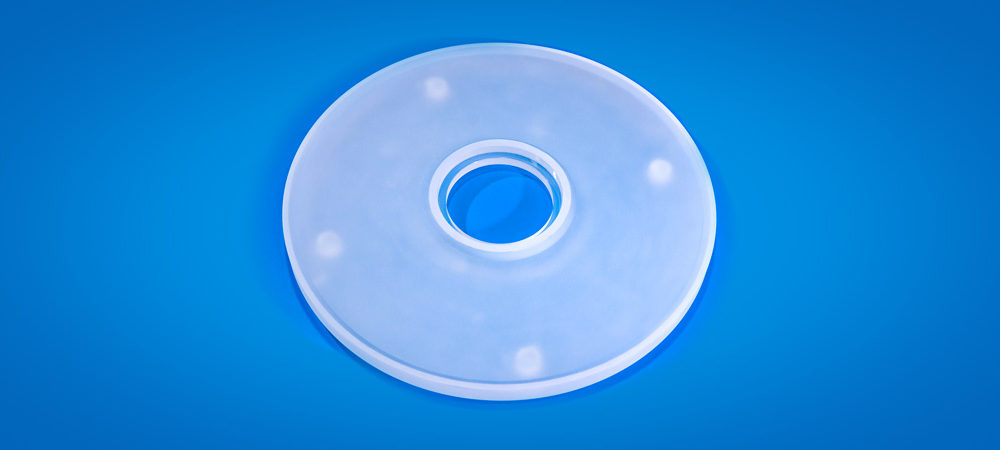

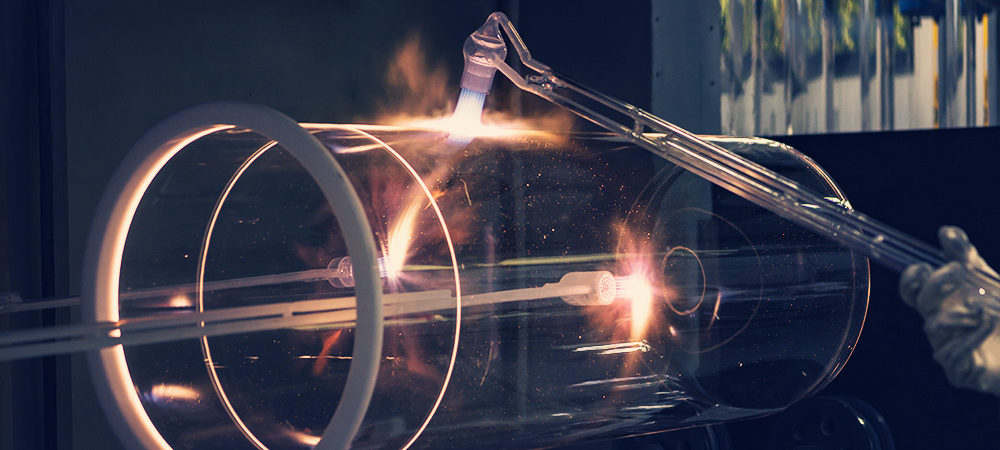

If you’re prototyping your design, we can work with you to support small quantity piece production. Our Photoveel machinable ceramic materials are ideal for prototyping and development. These unique materials enable us to machine precision features quickly, but have material characteristics that significantly outperform traditional glass ceramics.

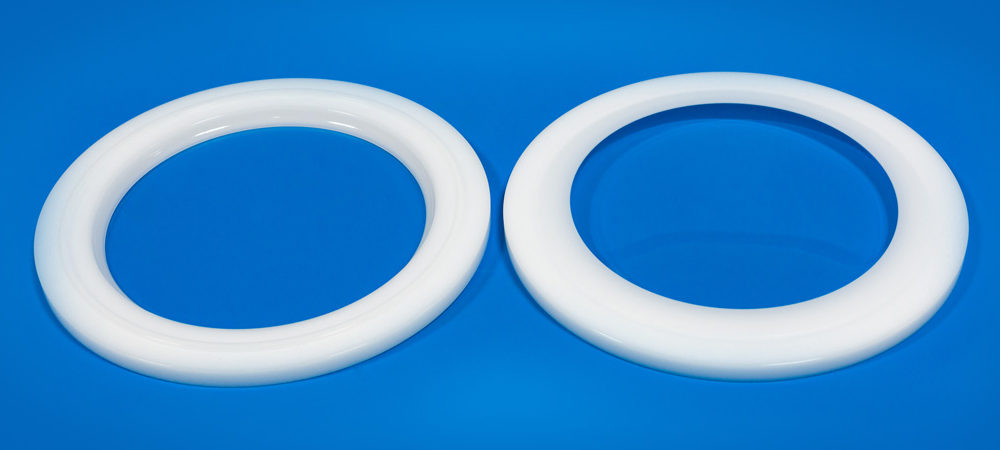

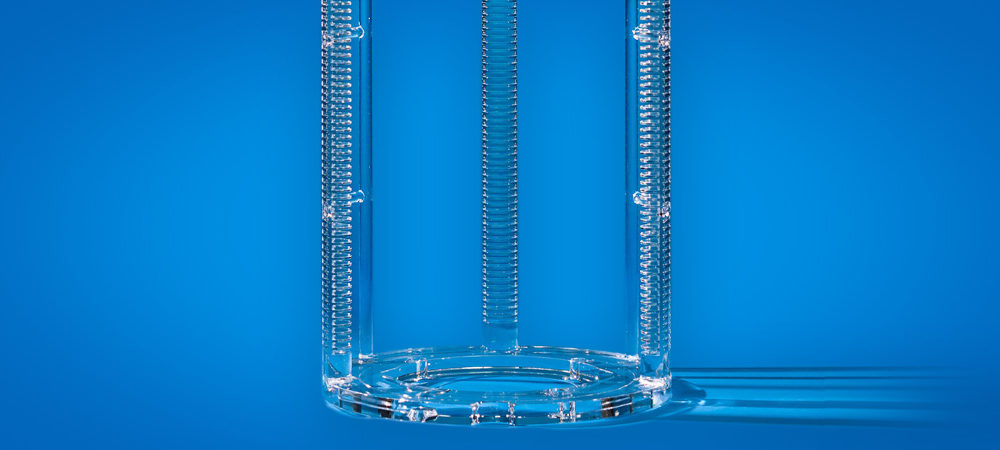

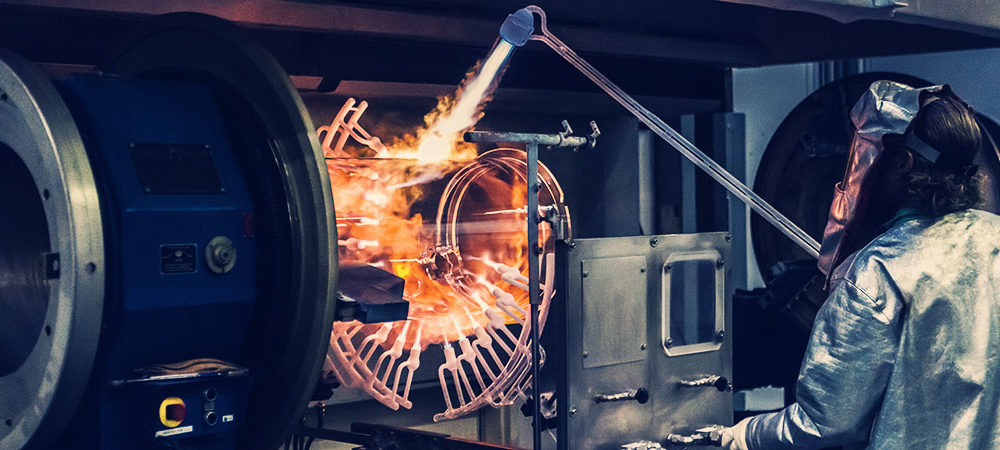

LTD Material, LLC has the talent and experience to prototype simple to highly complex quartzware. We are used to making what others say “could not be built." From prototype to ramping up for volume production, we have the capacity to support your volume production requirements and build fixtures in-house to speed up the ramp. If you’re currently buying parts from another supplier, our copy exact capabilities makes LTD Material, LLC an excellent second-source alternative.

Support of Second Sourcing Activities

We understand that customers cannot rely just on one source for ceramic or quartz spare parts. This is why we are geared up to provide parts that either meet or exceed the current state-of-the-art parts. Our experience in transferring production and receiving transfers has prepared us well to analyze your current supply and in turn, reproduce the current quality. This ensures your process can seamlessly use our parts. Minimizing variability is so critical to consistent tool-up time.

We also have experience developing internal drawing from parts. This is usually the case where the parts deviate from current available drawings. Whether it's providing OEM-certified parts or an engineered solution, we can support you.

Customer Process Improvement

Our technical sales team meets with customers to review challenges they are facing in their production on a regular basis. Not only does the team have many hours logged in the fab solving problems but they also have a broad experience from helping multiple customers producing multiple product types. Each product type has its own set of challenges.

Either through existing proprietary production technology or developing new novel approaches, our team has a proven track record of customer process improvement. These improvements have taken the form of wafer defect reduction, increased MTBM, Reduction in breakage, total cost of ownership, etc. All resulting in cost reductions to our customers.

Design

LTD Material, LLC verifies each customer drawing and specification prior to programming and manufacturing the part. The review is comprehensive to ensure the manufacturability of the part. We are able to simulate production of the part ensuring the highest quality from the start.

When the customer shares the intended application, our team is able to evaluate the part and identify critical to function features. We then select the processes for fabrication that ensure the highest repeatability for these critical features.

With the customer application in mind, the team also evaluates the stated material and overall part structure for fit. If they feel a different material or a change in the design will perform better, the customer receives a proposal.

Prototyping

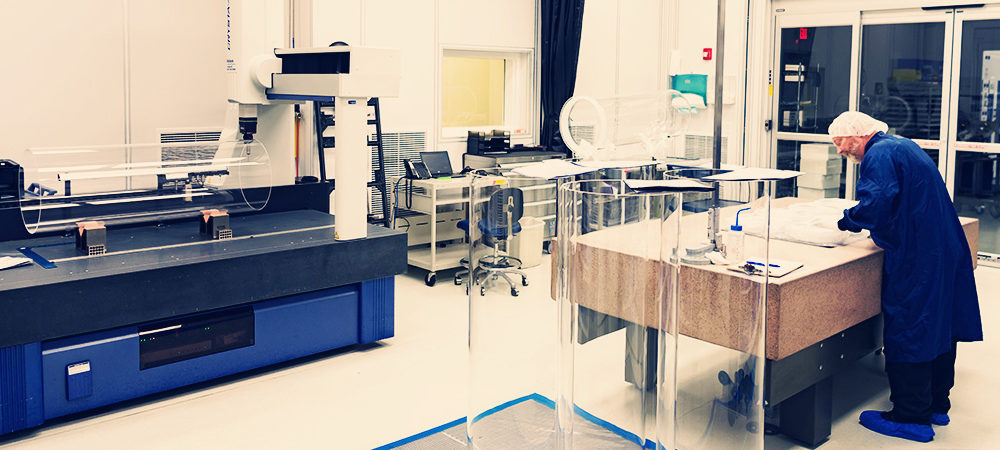

CMM / Drawing Services

ISO 9001- 2015 Certified

LTD Material, LLC has achieved ISO 9001-2015 certification (Certificate Registration # 10017682 QM15) to ensure that quality is held to the highest standards when designing, fabricating, and delivering a product line. The cornerstone of our business philosophy has been based on providing the best possible service, superior workmanship, and customer satisfaction that exceeded expectations. The ISO 9001- 2015 certification we received is shared across our team to ensure that “Quality” is the result of our daily work and in every shipment that we deliver to our customers. We are fully equipped with a complete inspection facility, including Helium leak check capability and several fully automated Mitutoyo Coordinate Measuring Machines.

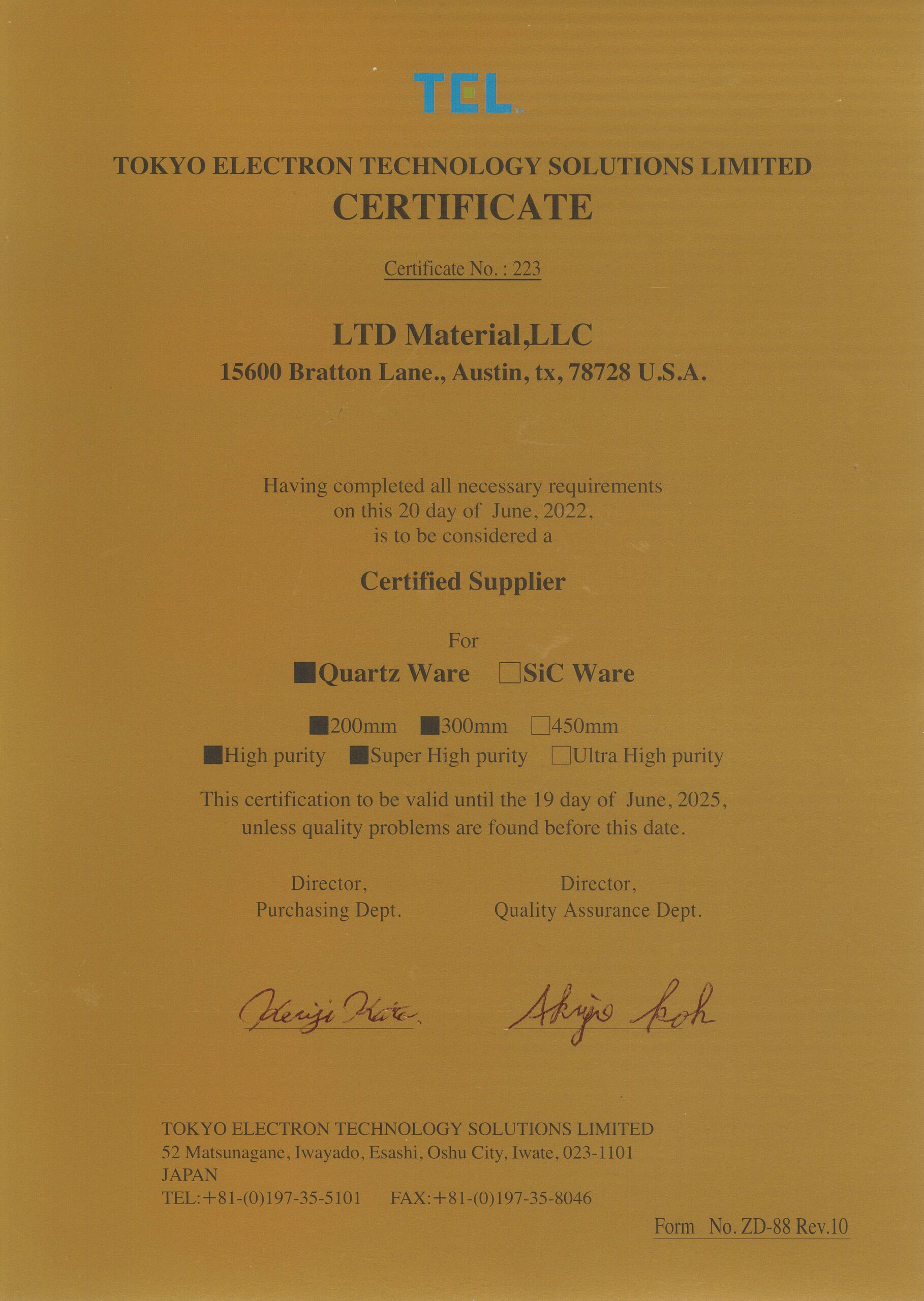

OEM Qualifications

Related Products and Processes